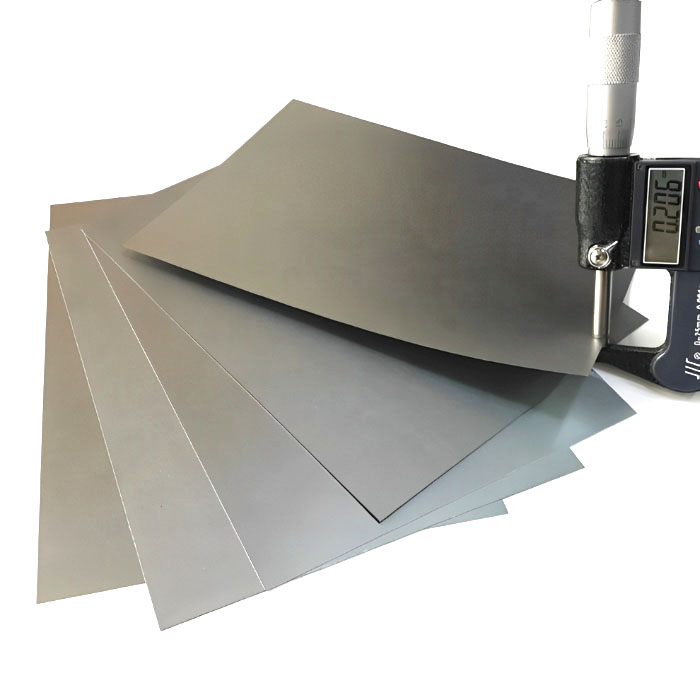

I-Tungsten Heavy Alloy (WNIFE) Rod

Inkcazo

Ubuninzi be-tungsten intonga ye-alloy enzima ukusuka kwi-16.7g/cm3 ukuya kwi-18.8g/cm3.Ubunzima bayo buphezulu kunezinye iintonga.Iintonga ze-Tungsten ezinzima ze-alloy zineempawu zokushisa okuphezulu kunye nokumelana nokubola.Ukongeza, i-tungsten heavy alloy rods inokumelana nokothuka okuphezulu kunye neplastikhi yomatshini.

Iintonga ze-Tungsten ezinzima ze-alloy zihlala zisetyenziselwa ukwenza iinxalenye zehamile, ukukhusela kwi-radiation, izixhobo zokukhusela emkhosini, ii-welding rods kunye neemodeli ze-extrusion.Ikwayenye yezinto zokuvelisa izixhobo kunye neembumbulu.

Iipropati

| IiPropati zoXina kunye noBulukhuni, i-ASTM B777 | |||

| Iklasi | Ucoceko lweTungsten, % | Ubuninzi, g/cc | Ubunzima, Rockwell"C", max |

| Iklasi yoku-1 | 90 | 16.85-17.25 | 32 |

| Iklasi yesi-2 | 92.5 | 17.15-17.85 | 33 |

| Iklasi yesi-3 | 95 | 17.75-18.35 | 34 |

| Iklasi yesi-4 | 97 | 18.25-18.85 | 35 |

| Ikakhulu i-tungsten yongeza umgubo onje ngobhedu, nickel okanye intsimbi. | |||

| iiPropati ze-echanical, i-ASTM B777 | ||||||

| Iklasi | Ucoceko lweTungsten, % | Ukomelela kokugqibela kokuqina | Amandla eSivuno kwi-0.2% Off-set | Elongation,% | ||

| ksi | MPa | ksi | MPa | |||

| Iklasi yoku-1 | 90 | 110 ksi | 758 MPa | 75 ksi | 517 MPa | 5% |

| Iklasi yesi-2 | 92.5 | 110 ksi | 758 MPa | 75 ksi | 517 MPa | 5% |

| Iklasi yesi-3 | 95 | 105 ksi | 724 MPa | 75 ksi | 517 MPa | 3% |

| Iklasi yesi-4 | 97 | 100 ksi | 689 MPa | 75 ksi | 517 MPa | 2% |

| Ikakhulu i-tungsten yongeza umgubo onje ngobhedu, nickel okanye intsimbi. | ||||||

Iimbonakalo

Ngaphandle koxinano oluphezulu kunye nokufunxa ngemitha, iipropathi ezininzi ezixabisekileyo ezinxulumene nobunzima obuphezulu kunye nokumelana zisetyenzisiwe kwinani elikhulu lezicelo.I-Tungsten i-alloy enzima ye-alloys yentsimbi ephikisayo ekwazi ukumelana nobushushu kunye nokunxiba.I-alloy ye-Tungsten enzima isetyenziswe ngokusisiseko ukwenza amacandelo afuna ukuxhathisa ukunxiba okuphezulu njengezixhobo zomatshini kubandakanya iileyile kunye needayisi.

Ifumana ukuncitshiswa okuncinci kwiimpawu zayo nakwiqondo lokushisa eliphezulu kwaye inokumelana nokugqoka okuphezulu.Ke ngoko, ii-alloys zeTungsten zisetyenziselwa izixhobo zoomatshini ezinje ngeelathe, oomatshini bokugaya, njl., kunye nokuvelisa iinxalenye zemoto ezinjengeenjini, ukuhanjiswa, ukuqondisa, njl., ezinegalelo ekuphuculeni ukuchaneka komatshini.

Ukwandiswa kwe-thermal ephantsi

I-thermal ephezulu kunye ne-conductivity yombane

Ukumelana ne-arc ephezulu

Ukusetyenziswa okuphantsi

Usetyenziso

I-Tungsten i-alloy enzima igqwesileyo kwizicelo ezifuna ukusebenza okuphezulu kwi-corrosion resistance, uxinaniso, ukuchaneka, kunye nokukhusela kwimitha.Ke ngoko, oku kuyenza ilungele ukusetyenziswa ekwenzeni intsimbi, imigodi, i-aerospace, kunye namashishini ezonyango.