Sinikezela ngeemveliso ezikumgangatho ophezulu

Iimpawu zeMveliso

-

I-Molybdenum Copper Alloy, i-MoCu Alloy Sheet

I-alloy ye-Molybdenum copper (i-MoCu) yimpahla edibeneyo ye-molybdenum kunye nobhedu ene-coefficient yokwandisa i-thermal kunye ne-thermal conductivity.Inoxinano olusezantsi kodwa iphezulu CTE xa kuthelekiswa netungsten yobhedu.Ngoko ke, i-alloy yobhedu ye-molybdenum ifanelekile ngakumbi kwi-aerospace kunye nezinye iindawo.

I-alloy yobhedu ye-Molybdenum idibanisa iingenelo zobhedu kunye ne-molybdenum, amandla aphezulu, ubunzima obuphezulu obuphezulu, ukumelana nobushushu obuphezulu, ukuxhathisa kwe-arc ablation, ukuhanjiswa kombane okulungileyo kunye nokusebenza kokufudumeza, kunye nokusebenza kakuhle kokusebenza.

-

I-Molybdenum Lanthanum (MoLa) I-alloy Boat Tray

I-tray ye-MoLa isetyenziselwa ikakhulu iintsimbi okanye i-sintering kunye nokufaka i-non-metals phantsi kwe-atmosphere yokunciphisa.Zisetyenziselwa ukucwiliswa kwesikhephe kwiimveliso zomgubo ezifana neeseramikhi ezicoliweyo.Ngaphantsi kobushushu obuthile, i-alloy ye-molybdenum lanthanum kulula ukuphinda ifakwe kwikristali nto leyo ethetha ukuba akukho lula ukukhubaza kwaye inobomi obude benkonzo.I-tray ye-Molybdenum lanthanum yenziwe ngokugqwesileyo ngokuxinwa okuphezulu kwe-molybdenum, iipleyiti ze-lanthanum kunye nobuchule obugqwesileyo bokusebenza.Ngokuqhelekileyo i-molybdenum lanthanum tray icutshungulwa nge-riveting kunye ne-welding.

-

I-Molybdenum Lanthanum (Mo-La) iAlloy Wire

I-Molybdenum Lanthanum (i-Mo-La) yi-alloy eyenziwe ngokudibanisa i-Lanthanum Oxide kwi-molybdenum.I-Molybdenum Lanthanum Wire ineempawu zobushushu obuphezulu bokubuyisela icrystallization, i-ductility engcono, kunye nokugqwesa ukunxiba.IMolybdenum (Mo) ingwevu-yesinyithi kwaye inendawo yesithathu ephezulu yokunyibilika kwayo nayiphi na into ecaleni kwetungsten kunye netantalum.Iingcingo zemolybdenum ezinobushushu obuphezulu, ezikwabizwa ngokuba zii-Mo-La alloy ingcingo, zezemathiriyeli yezakhiwo ezinobushushu obuphezulu (izikhonkwane zokushicilela, amandongomane, nezikrufu), izibambi zezibane ze-halogen, izinto zokufudumeza iziko lobushushu obuphezulu, kwaye zikhokelela kwiquartz kunye neHi-temp. izinto ze-ceramic, njalo njalo.

-

I-Molybdenum Lanthanum (MoLa) Amacwecwe engxubevange

Ingxubevange ye-MoLa inokwakheka okuhle kuwo onke amanqanaba ebakala xa ithelekiswa nemolybdenum esulungekileyo ekwimeko efanayo.Imolybdenum esulungekileyo iphinda ibe yikristale malunga ne-1200 °C kwaye iba brittle kakhulu inobude obungaphantsi kwe-1%, nto leyo eyenza ukuba ingenzeki kule meko.

Ingxubevange ye-MoLa kwipleyiti kunye neefomu zeshiti zisebenza ngcono kune-molybdenum esulungekileyo kunye ne-TZM kwizicelo zobushushu obuphezulu.Oko kungaphezulu kwe-1100 °C kwi-molybdenum nangaphezulu kwe-1500 °C kwi-TZM.Obona bushushu bucetyiswayo kakhulu kwi-MoLa yi-1900 °C, ngenxa yokukhutshwa kwamasuntswana e-lanthana ukusuka kumphezulu wobushushu obungaphezulu kwe-1900 °C.

"Ixabiso elingcono" i-alloy ye-MoLa yile iqulethe i-0.6 wt % lanthana.Ibonisa eyona ndibaniselwano yezakhiwo.Ingxubevange yeLanthana yeMoLa ilingana endaweni yeMo esulungekileyo kuluhlu lobushushu obuyi-1100 °C - 1900 °C.Iingenelo zeLanthana MoLa ephezulu, njengokuxhathisa okuphezulu kwe-creep, ziyenzeka kuphela, ukuba imathiriyeli iphinda iphinde isetyenziswe kumaqondo obushushu aphezulu.

-

Ubushushu obuphezulu iMolybdenum Lanthanum (MoLa) Al...

I-alloy ye-Molybdenum Lanthanum (i-alloy ye-Mo-La) yi-oksidi yokusabalalisa i-alloy eyomeleziweyo.I-alloy ye-Molybdenum Lanthanum (i-Mo-La) yenziwe ngokudibanisa i-lanthanum oxide kwi-molybdenum.I-Molybdenum Lanthanum alloy (i-alloy ye-Mo-La) ikwabizwa ngokuba yi-molybdenum yomhlaba enqabileyo okanye i-La2O3 i-doped molybdenum okanye i-molybdenum ephezulu.

I-Molybdenum Lanthanum (Mo-La) Ingxubevange ineempawu zobushushu obuphezulu bokubuyisela icrystallization, i-ductility engcono, kunye nokugqwesa kokunganxibi.Ubushushu bokuhlaziya i-alloy ye-Mo-La bungaphezulu kwe-1,500 degrees Celsius.

I-alloys ye-Molybdenum-lanthana (i-MoLa) yolunye uhlobo lwe-ODS i-molybdenum equkethe i-molybdenum kunye noluhlu oluhle kakhulu lwe-lanthanum trioxide particles.Ubuncinci be-lanthanum oxide particles (0.3 okanye i-0.7 pesenti) inika i-molybdenum into ebizwa ngokuba yi-fiber structure.Le microstructure ikhethekileyo izinzile ukuya kuthi ga kwi-2000 ° C.

-

Iingcebiso zoMbhobho we-TZM wengxubevange yeeNkqubo zeMbaleki ezishushu

I-Molybdenum TZM – (Titanium-Zirconium-Molybdenum) ingxubevange

Inkqubo yembaleki eshushu yindibano yamacandelo ashushu asetyenziswa kwimibumbo yesitofu seplastiki esifaka iplastiki etyhidiweyo kwimingxuma yokubumba, ukufumana iimveliso zeplastiki ezikumgangatho ophezulu.Kwaye ngokuqhelekileyo yenziwe nge-nozzle, isilawuli sokushisa, ezininzi kunye nezinye iindawo.

I-Titanium zirconium molybdenum (TZM) i-nozzle yembaleki eshushu enokumelana nobushushu obuphezulu, ukomelela okuphezulu, ukuxhathisa okulungileyo kokuhlwa kunye nezinye iipropathi ezigqwesileyo, zisetyenziswa ngokubanzi kuzo zonke iintlobo zemveliso yombhobho wembaleki eshushu.Umbhobho we-TZM yinxalenye ebalulekileyo yenkqubo yembaleki eshushu, ngokomlomo okwimo yokumila inokwahlulwa ibe ziintlobo ezimbini eziphambili, isango elivulekileyo kunye nesango levalvu.

-

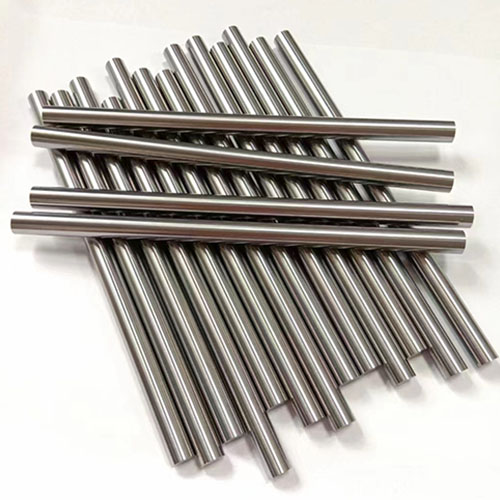

Umgangatho ophezulu we-TZM Molybdenum Alloy Rod

I-TZM Molybdenum yi-alloy ye-0.50% ye-Titanium, i-0.08% ye-Zirconium, kunye ne-0.02% yeCarbon ene-balance Molybdenum.I-TZM Molybdenum yenziwe yi-P/M okanye i-Arc Cast technologies kwaye iluncedo kakhulu ngenxa yamandla ayo aphezulu/ubushushu obuphezulu bezicelo, ingakumbi ngaphezulu kwe-2000F.

I-TZM iMolybdenum inobushushu obuphezulu bokubuyisela ikristale, amandla aphezulu, ubulukhuni, i-ductility elungileyo kwiqondo lobushushu begumbi, kunye namaqondo obushushu aphezulu kuneMolybdenum engafakwanga.I-TZM inikezela ngokuphindwe kabini amandla e-molybdenum ecocekileyo kumaqondo obushushu angaphezu kwe-1300C.Iqondo lobushushu le-recrystallization ye-TZM limalunga ne-250°C, lingaphezulu kune-molybdenum, kwaye linika ukuwelda okungcono.Ukongeza, i-TZM ibonisa i-thermal conductivity elungileyo, uxinzelelo lomphunga oluphantsi, kunye nokuxhathisa okulungileyo kokuhlwa.

I-Zhaolixin yenza i-alloy ye-oxygen ephantsi ye-TZM, apho umxholo we-oxygen unokuthotywa ukuya ngaphantsi kwe-50ppm.Ngomxholo ophantsi we-oksijeni kunye neencinci ezincinci, ezihlakazwe kakuhle ezinemiphumo ephawulekayo yokomeleza.I-alloy yethu ye-oxygen ephantsi ye-TZM inokumelana okugqwesileyo, ubushushu obuphezulu bokwenza iikristale, kunye namandla angcono obushushu obuphezulu.

-

Umgangatho ophezulu weMolybdenum Alloy Products TZM Allo...

I-TZM (i-titanium, i-zirconium, i-molybdenum) i-Alloy Plate

I-alloy yokuqala ye-Molybdenum yi-TZM.Le alloy iqulethe 99.2% min.Ukuya kuma-99.5% ubukhulu.I-Mo, i-0.50% ye-Ti kunye ne-0.08% ye-Zr kunye nomkhondo we-C wokubunjwa kwe-carbide.I-TZM inikezela ngokuphindwe kabini amandla e-moly ecocekileyo kumaqondo obushushu angaphezu kwe-1300′C.Ubushushu bokwenziwa kwakhona kwe-TZM bumalunga ne-250′C ngaphezulu kwe-moly kwaye inika ukuwelda okungcono.

Ubume obucolekileyo obuziinkozo be-TZM kunye nokusekwa kwe-TiC kunye ne-ZrC kwimida yeenkozo ze-moly inhibisa ukukhula kweenkozo kunye nokusilela okunxulumeneyo kwesiseko sesinyithi ngenxa yokwaphuka ecaleni kwemida yeenkozo.Oku kunika iipropati ezingcono zokuwelda.I-TZM ixabisa malunga ne-25% ngaphezulu kwe-molybdenum ecocekileyo kwaye ixabisa kuphela malunga ne-5-10% ngaphezulu kumatshini.Ukusetyenziswa kwamandla aphezulu njengemibhobho yerokethi, amacandelo okwakhiwa kwesithando somlilo, kunye nokufa kwe-forging, kunokulixabisa ixabiso elahlukileyo.

Sithembe, sikhethe

Ngathi

Inkcazo emfutshane:

ILuoyang Zhaolixin Tungsten&Molybdenum Materials Co., Ltd. ibekwe eLuoyang, ikomkhulu lamandulo lee-dynasties ezisithoba.Lishishini elikhethekileyo kwimveliso enzulu kunye nokusetyenzwa kweTungsten, iMolybdenum, iTantalum, iNiobium kunye neemveliso zayo zealloy, kunye nokwenziwa kweziko lokufunxa kunye nokujoliswe kuko.Inkampani ikwisiXeko saseLuoyang, eTshayina, indawo yokuzalwa yenkcubeko yamaTshayina kunye nesiseko semizi-mveliso esibalulekileyo saseTshayina esinamandla okuvelisa.I-Luoyang Zhaolixin inamandla okuvelisa i-sintering, i-isostatic eshushu yokucinezela, ukuqengqeleka, ukubumba, i-sheet metal, kunye ne-machining ye-Tungsten, i-Molybdenum, i-Tantalum kunye neemveliso ze-Niobium.