I-Molybdenum ecocekileyo ye-Thermal Spray Wire yeGalling kunye ne-Scuffing Resistance

Uhlobo kunye nobukhulu

I-Zhaolixin Tungtsen kunye ne-Molybdenum inokubonelela ngocingo lwe-molybdenum ngokwemizobo kunye neemfuno zakho.

| Ububanzi (μm) | Ubunzima (mg/200mm) | Ubunzima (mg/200mg) Ukunyamezela (%) | Unyamezelo lweDiameter (%) | ||

| IBanga loku-1 | IBanga lesi-2 | IBanga loku-1 | IBanga lesi-2 | ||

| 20≤d<30 | 0.65~1.47 | ±2.5 | ±3 | ||

| 30≤d<40 | >1.47~2.61 | ±2.0 | ±3 | ||

| 40≤d<100 | >2.61~16.33 | ±1.5 | ±3 | ||

| 100≤d<400 | >16.33~256.2 | ±1.5 | ±4 | ||

| 400≤d<600 | ±1.5 | ±2.5 | |||

| 600≤d<3200 | ±1.0 | ±2.0 | |||

Iimbonakalo

| Iipropati | Metric | Impiriyali |

| Amandla okuqina (afakiwe) | 324 MPa | 47000 psi |

| Amandla okucheba (umyinge we-torsional strain 0.25/s) | 500 MPa | 72500 psi |

| Amandla esivuno esicinezelayo (0.01% isivuno) | 400 MPa | 58000 psi |

| Imodyuli ye-elasticity | 330 GPA | 47900 ksi |

| Imodyuli ye-elasticity kwiqondo lobushushu eliphakamileyo (@2000°C/3630°F) | 160 GPA | 23200 ksi |

| I-Thermal Coefficient yoKwandiswa: | 5 x 10-6 cm/cm @ 25 oC | |

| Ukuqhutywa koMbane: | 34% IACS | |

| I-Thermal Conductivity: | 1.38 W/cm/K @ 298.2 K | |

| Ukuxhathisa koMbane: | 5.2 microhm-cm @ 0 oC | |

I-Mo-wire imnyama rhoqo igqunywe ngegraphite.Emva kokuba i-graphite isusiwe i-metallic luster.

Usetyenziso

- Kumatshini wokusika ucingo

- Ukuvelisa iindawo zomthombo wokukhanya kombane kunye namalungu e-vaccum yombane

- Ukuvelisa izinto zokufudumeza kunye neengxenye eziphikisayo kwiindawo zokushisa eziphezulu

- Ukutshiza ukuguga kunye nokukrazula iinxalenye zemoto kunye nabanye oomatshini ukuphucula ukunxiba kwabo

- La2O3 okanye Y2O3 doped Refractory Mo-wire ziyafumaneka

Ubugcisa

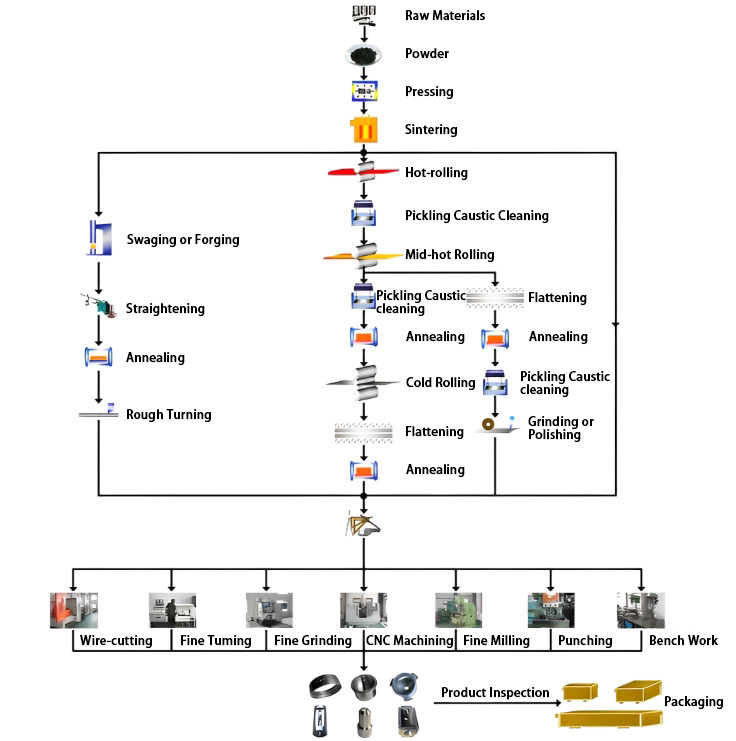

Impahla engekasilwa:Ukuqala kwizinto eziluhlaza, sikhetha izinto ezisemgangathweni ophezulu, obalasele kakhulu kuzinzo kunye nokuhambelana kweemveliso.Chonga iintlobo ezahlukeneyo zemathiriyeli ekrwada kwaye uphawule inombolo yebhetshi.Kwaye ibhetshi nganye yemathiriyeli ekrwada iya kwenziwa isampuli, ihlolwe kwaye igcinwe.Qinisekisa ukulandelwa kwemveliso nganye egqityiweyo kwaye ngokuqhubekayo uphucula umgangatho wemveliso.

Umgubo:Ulawulo lwenkqubo yokusila yeemveliso zesinyithi zeZhaolinxin ichanekile kakhulu, kunye nabaxube abaninzi kunye namaqonga okungcangcazela ukuze kuqinisekiswe ukuba izinto ezikwinkqubo yokucoca kunye nokuxuba zinokuvuswa ngokupheleleyo kwaye zisasazwe ngokulinganayo, ukuze kuqinisekiswe ukuhambelana kombutho wangaphakathi we iimveliso.

Ukucinezela:Kwinkqubo yokudibanisa umgubo, umgubo ucinezelwa sisixhobo sokucinezela isostatic ukwenza ubume bayo bangaphakathi bufanane kwaye buxinene.I-Zhaolixin inomngundo ogqibeleleyo webhetshi, kwaye inezixhobo zokucinezela isostatic ukuhlangabezana nokuveliswa kweebhetshi ezinkulu zeemveliso.

Sintering:Kwi-metallurgy ye-powder, emva kokuba i-powder yensimbi yenziwe ngokucinezela i-isostatic, ifudumala kwiqondo lokushisa elingaphantsi kweqondo lokunyibilika lamacandelo aphambili ukwenza iinqununu zidibanise, ukwenzela ukuba kuphuculwe ukusebenza kweemveliso, ezibizwa ngokuba yi-sintering.Emva kokuba umgubo wenziwe, umzimba oshinyeneyo ofunyenwe nge-sintering luhlobo lwemathiriyeli ye-polycrystalline.Inkqubo ye-sintering ichaphazela ngokuthe ngqo ubungakanani beenkozo, ubungakanani bepore kunye nokumila komda wengqolowa kunye nokusabalalisa kwi-microstructure, eyona nkqubo ingundoqo ye-metallurgy powder.

Ukuqulunqa:Inkqubo yokubumba inokwenza ukuba izinto eziphathekayo zifumane ukuxinana okuphezulu, iimpawu ezingcono zoomatshini, kwaye zidlale indima ekomelezeni umphezulu.Ukulawulwa ngokuchanekileyo kwezinga lokucubungula kunye nokushisa kwe-tungsten kunye ne-molybdenum yinto ebalulekileyo yokusebenza okuphezulu kwe-Zhaolixin tungsten kunye ne-molybdenum.Indlela yokucubungula yokusebenzisa umatshini wokugaya ukufaka uxinzelelo kwintsimbi engenanto ukuze iguqulwe ngeplastiki ukuze ifumane i-forging eneempawu ezithile zomatshini, imilo ethile kunye nobukhulu.

Ukuqengqeleka:Inkqubo yokujikeleza yenza ukuba izinto zetsimbi zivelise i-deformation yeplastiki eqhubekayo phantsi koxinzelelo lomqulu ojikelezayo, kwaye ufumane icandelo elifunekayo imilo kunye neempawu.Nge-tungsten ephezulu kunye ne-molybdenum ebandayo kunye ne-teknoloji eshushu yokuqengqeleka kunye nezixhobo, ukusuka kwi-tungsten kunye ne-molybdenum yesinyithi engenanto ukuya kwimveliso ye-tungsten kunye ne-molybdenum foil, i-Zhaolixinguarantees uphucula ngakumbi iteknoloji yokuvelisa kunye neempawu zentsimbi eziphezulu.

UkuNyanga ubushushu:Emva kwenkqubo yokugoba kunye nokuqengqeleka, izinto eziphathekayo ziphantsi kwenkqubo yonyango lokushisa ukuphelisa ngokupheleleyo uxinzelelo lwangaphakathi lwesakhiwo, ukunika umdlalo ekusebenzeni kwezinto, kunye nokwenza izinto zibe lula kumatshini olandelayo.I-Zhaolixin inezixhobo ezininzi zokufunxa kunye nobushushu bonyango lwe-hydrogen eziko ukuhlangabezana nokuhanjiswa ngokukhawuleza kwee-odolo zemveliso yobuninzi.

Oomatshini:Izinto eziphathekayo zeZhaolixin ziye zafumana unyango olupheleleyo lobushushu, kwaye emva koko zicutshungulwa kwiisayizi ezahlukeneyo ezenziwe ngokwezifiso ngokusetyenziswa kwezixhobo ezifana nokujika, ukugaya, ukusika, ukugaya, njl., kwaye iqinisekisa ukuba intlangano yangaphakathi ye-tungsten kunye ne-molybdenum iqinile, ayinaxinzelelo. kwaye ingenamngxuma, enokuthi ihlangabezane neemfuno zabathengi.

Ukuqinisekisa umgangatho:Ukuhlolwa komgangatho kunye nolawulo kuya kwenziwa kwimathiriyeli ekrwada nakwinyathelo ngalinye lemveliso, ukuze kuqinisekiswe ngokuqhubekayo umgangatho wemveliso nganye.Ngexesha elifanayo, xa iimveliso ezigqityiweyo zihanjiswa kwindawo yokugcina impahla, ukubonakala, ubungakanani kunye nombutho wangaphakathi wezinto eziphathekayo zivavanywa nganye nganye.Ngoko ke, ukuzinza kunye nokuhambelana kweemveliso zibalaseleyo.